A couple months back, I had been seeing some tweets from Grant Castelluzzo and Mike Hinkens about some new wax they were cooking up for their selves to ride with. They were talking about testing and all these different things. For some reason the past year or so, a lot of different brands have been putting out their own wax but none seem to be as unique as what these guys were doing. It didn’t quite click until closer to them dropping the news that they were actually starting up their own company. Last week they launched the brand they are calling Our Wax with their new website and a promotional web video giving you a look at the product and some riding. We figured it would be cool to get ahold of them and find out what exactly they are doing. Let’s find out exactly what Our Wax is all about…

Let’s take this from the start. When did you [Mike Hinken] and Grant Castelluzzo decide you wanted to get into the wax business? Did you guys ever intend on making it into a company or was it just supposed to be some small runs for friends?

Well, we never really had the intention of starting a “company” per se. Coming home from Austin this last Christmas we were bored and talking about how much most wax sucks. And how there actually is some science behind all of it. We started talking about how we could make something better if we had the resources. We had been getting scraps of all sorts of wax from my girlfriend’s mom who makes candles at home. Some were hard. Some were soft. And we started realizing that different consistencies were ideal for different situations. We also realized that we’re using some other industry’s product as a mainstay of our riding experience. Seemed silly. Just as silly as using a Schwinn Stingray for riding street. Times changed and products evolved. At the end of the 22 hour drive we were resolved to make a mold and try to make a wax designed to be used by riders. we talked about selling it, but really, just wanted to see if we could even do it and if it would work.

Why wax? Did you guys ever consider doing anything else or was it just something you guys needed?

This project has been the result of necessity, curiosity, and availability. We wanted to change something that we used regularly and didn’t like: wax. We also were just wondering if it was possible for us to make it work. Learning is always fun. Until you burn the house down with your pseudo-meth lab. And finally, we had the resources to try to do it. If we wanted to forge new pegs or something, we would have been outta luck. We don’t have any friend’s moms who have a machine shop at home. Having a seasoned wax maker in the family made it possible.

What were the first steps in making this a reality?

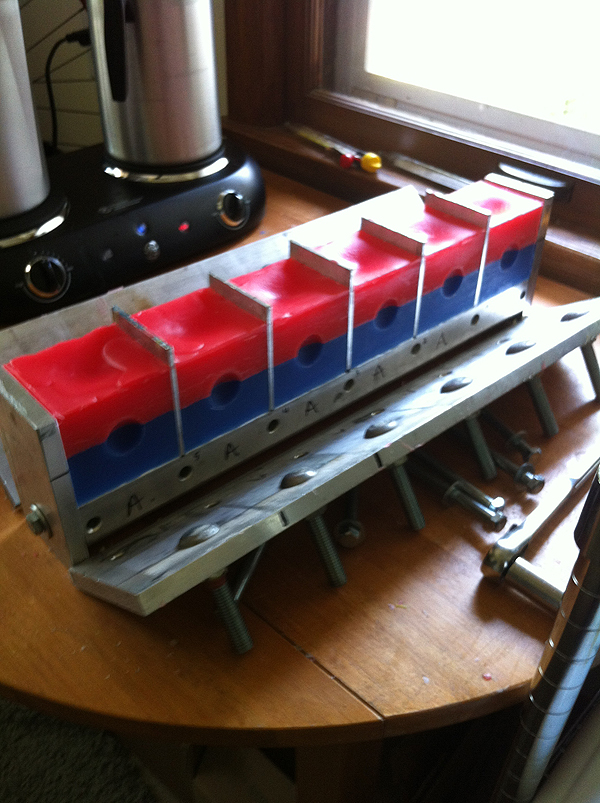

We knew someone who could pour wax, we needed to decide what it would look like and how to get that shape produced. We bought some crayola sculpting clay and made a model of what we imagined. That was cheap and fun. The next step was the first major roadblock: a mold. We do actually know some machinists, but turning a clay model into a reverse mold that could handle 200 degree wax proved to be expensive. Even with connections to Profile/Madera, machining a mold was impossibibly expensive. We turned to our friend Kyle Kompas who proved that the simplest answer is usually best. $55 and a lot of calculations, machining And swearing brought us to our first mold. Now to pour

If I remember right, you guys had a pretty heavy learning curve with how wax works and you guys did quite a bit of testing to find the best wax. Care to share a little bit about your experience when you first got started?

As I mentioned above, we had a mentor for sure. Once we got a mold working it was figuring out the types of wax that took some time. We took samples of chunks of wax with different properties and applied them to ledges, rails, etc. testing was fun, since it was just riding stuff and feeling out the lubrication. Once we picked some formulas, we handed over the melting and production to my girlfriend’s mom. We didn’t have the stuff To make and pour wax, nor the experience. She made us about 5 prototypes and we then tested the shape, the consistency and finally, the bond between the two waxes. That was harder and we were worried about this the most. Would two types of waxes stay together with the stress we put on em? We took a few and whipped em at walls and tugged on em. Surprisingly, we have never broke one yet.

How are you guys making your wax now? Do you have somebody make it for you guys, or are you still doing it on your own as always?

After we figured out all the details above, it was time to take it to the next level. We invested in a bigger mold with some modifications after testing. By bigger, I mean, we can pour 6 at a time. Next, we worked closely with Janet to Learn the process. She taught us the art of pouring wax. Its not rocket science, but it’s not easy. Temperatures and timing are really important and for impatient and busy dudes, we learned we would have to be attentive and careful. Ha. Next step was doing it ourselves. We bought all sorts of supplies and set up a little shop in our dining room. We are calling it “The Waxtory.” Now, we do it all in house, literally. It takes about 3 hours from start to finish to finish a mold. Then about 6 hours to cool for release. In other words, we can presently do one or two batches a day. That’s “mass” production for us for now.

Care to talk about the whole purchasing of supplies side of things? I feel like that’s a pretty interesting side of things people don’t really think about when they hold a block of wax.

It’s messy. Ha. I have tried to standardize where and how we get our stuff in order to understand cost, but it’s not so easy. When you make a product you really need to know all costs of making it, and down to the penny, to help understand what you can sell it for and your profit. We were lucky to be given a ton of leftover scents and colors, so we have not had to pay for that expensive part of the process yet. We buy in bulk through Janet and one of her suppliers. We work with amounts in the hundreds of pounds so shipping is a huge cost. Wax, being petroleum based, is not cheap and not getting any cheaper. So we get hit as shipping prices increase for fuel costs and as petroleum products go up in general. Either way, a big heavy box shows up at the door and we need to smash and break up that expesive raw material.

A lot of people don’t really realize how much it takes to run a business until they’re really getting things rolling. What are some of the things you have been dealing with beyond the whole “make the wax and sell it”?

This has been a learning experience for sure. We immediately knew we needed a website and an online store. Having one built proved too expensive so we played with a pre-made site and used some of my basic HTML skills to modify it. I learned a tiny bit of HTML just from this kinda stuff. Then we had to buy our domain. Learned all about the backend of a website…and how little I understand. The website has been fun and creative, but the online store has been complex. When you start selling you need a legitimate way to do so. For us, that has been a PayPal. Setting that up has also been challenging. We are in the midst of figuring out taxes and how that will affect us. It’s here that costs we never thought of come into being. How much does a bag cost, a box, shipping, Pay Pal fees, tax? All of these things changed our cost and profit margin. Not as much money in this as we may have projected. But, we really don’t care at the moment. We like what we are making and stand behind it. If we really wanted to make money, we would have to outsource and sell it mass quantities. Something we aren’t doing right now. We also need to focus our funds on basic things like incorporating and getting patents.

What does your product line look like these days? Do you offer just one kind of wax or do you have different types for different setups? Do you guys plan on doing shirts, stickers and other things in the future?

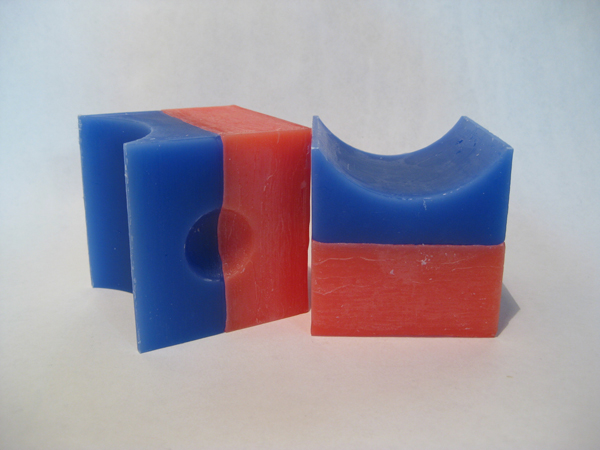

As of right now we sell one model. That model is our flagship in a sense. It embodies all the issues we wanted to address in a versatile wax for all uses. Every batch is made of two different colors and has a unique scent. You can order from a varied selection of unique combinations but they are all the same shape and formulas for the same price. We are keeping it super simple for now. No stickers, shirts, or swag. We are thinking of selling a large brick shaped model comprised of only soft wax for taking a raw ledge from unrideable to heaven. More to come on the butter brick later.

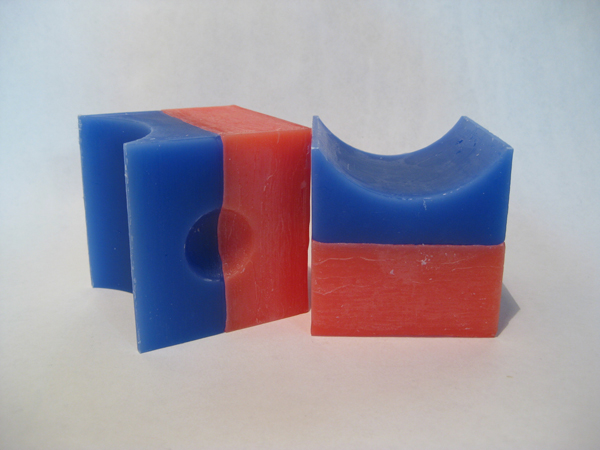

You guys put some thought into the design of the wax too, right? Care to explain why you chose to do the shape and material you guys have?

This is really the core of it all. Our Wax is a homemade wax designed with grinding in mind. Each obstacle is

different and as a result, riders need a wax that works in various situations. Ledges are made of different materials than rails and therefore act differently with pegs and waxes. Our Wax has a soft side that is perfect for rough ledges, unwaxed surfaces and porous materials. It is designed to apply easily and in thick amounts to fill in cracks and imperfections. Our Wax also has a hard side that is designed for use on metal, smooth surfaces, or already waxed obstacles. Things that are smooth dont need a paste like wax. These surfaces get slower with soft wax. Our hard formula is better for them. The finger hold design is intended to avoid smashed and grinded knuckles while allowing for an easy application of the wax. When you are giving a ledge hell, you need a good grip! Finally the shapes are designed for actual use. Some companies make cool looking wax shapes, but when you use them, they break, crumble, or are just inefficient. The arched side of Our Wax fits on almost any rail. Its awesome to be able to ride past a rail holding the wax while it just waxes all parts of it. The flat side is simple and straightforward. It’s a large chunk for use on ledges.

Are there any other people involved with the brand outside of you two?

At the moment, it’s just Grant and I as the investors and owners. My girlfriend and her mother are advisers and occasional helpers now. We have had some interest in investment, but at the moment we are staying small and DIY. We want to see where this takes us for now.

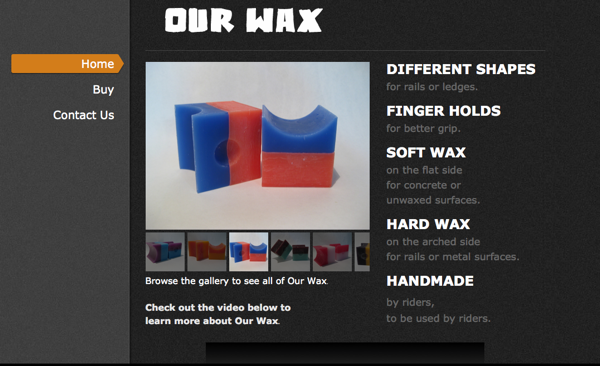

Where can people pick up the wax? Do you have a website? How can shops or distributors get ahold of you to make an order?

As of right now we are only doing online orders from our online shop/website at http://www.OurWax.com. From our website you can head to the online store and order direct. We are making contacts with shops for future shop orders. We just dont have the stock to sell en masse to shops at the moment but we are contemplating how to change that as we gauge demand. We have a contact form on the website for dealer inquiries and any other questions. we hope to hear from more shops soon. Also, follow us on twitter for quick updates on new colors and scents and limited runs of special edition waxes. (Green Bay Packers season is just around the corner!) We also have a Twitter for people to hit us up on @OurWax.

Prototype of their Green Bay Packers wax. Where’s the purple and gold?

Do you guys have any edits, trips or anything promotional wise lined up for the brand?

We made an introduction to OurWax video that you can view on our home page. It shows a very abbreviated version of the wax-making process, how to apply it, and some bike riding demonstrations. As for future edits, that is yet to be determined. We really are trying a grassroots approach in the hopes that the quality of our product will sell itself. Maybe that’s a bad choice, but, we have a tiny bit of experience in the usual channels of BMX sales, so we can always change directions. Ha.

Where do you see yourself going with this in the future? Would you ever want to do something like this full-time?

The future is very unknown to us at this moment. This could take off and we could turn this into a big deal. Or, more realistically, it will be self-sustaining and continue on as a side project for us. At the moment, it’s fun, manageable, and interesting. I doubt this will ever become a full-time thing. We have had some interest from people in making unique waxes for them and their companies though. We have no expectations and hope to continue to have fun.

What kind of advice do you have for people out there looking to start a business? What about a business in the BMX industry?

As for a small business in general: do your homework. Things are way more complex than you can imagine. Coming in as an idealist may end you end up disillusioned. Money is the biggest issue. That, and work. We don’t have a lot of money, but at every turn we are spending it. From paper towels to wax to Pay Pal fees. It all adds up. We don’t have any illusions of making a ton of money. With all the labor we have put in as well, we are really working for free at this point. As for a business in the BMX industry, that’s a much bigger answer. I won’t dive to deep into this, but I will say, being part of the BMX industry is all about knowing your audience. Strangely, people who ride BMX are super informed about some stuff, yet blind to other things. Understanding what kids care about and don’t care about is a huge issue. You can take our best guess as to what kids think, but make it a good one. They may not care that something is a great product, but care who rides it. Or, they may not care about price, if they know it’s a great product. The dichotomies are endless. We hope that people will look at OurWax and see that we are selling something that doesn’t really exist like we have made it and that our product should make your bike riding experience better. This comes from two guys who are real bike riders and use this stuff daily. After all, we made it for ourselves!

Is there anything I missed that you want to add?

I think thats it man. Thanks a ton!