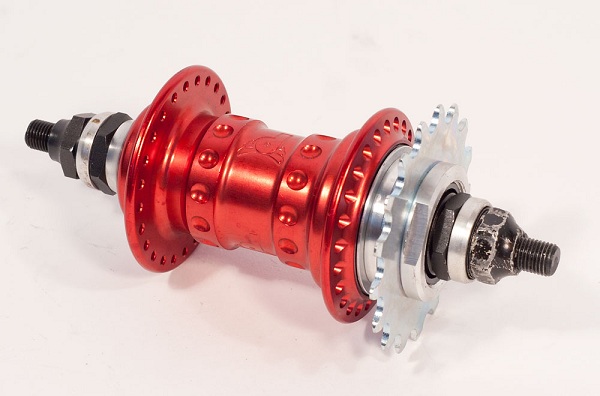

BMX bikes have come a long way over the past 20-30 years, from rattling 1 Inch Threaded Headsets and shin searing Beartrap Pedals to investment-cast Dropouts and Pivotal Seats. Along the way there have been several products which have been instrumental to the improvement of our bikes, and at the top of that list is the Profile Cassette Hub. 15 years ago the guys at Profile took a technology used on high-end road bikes and used it to create, what is still to this day one of the most reliable and functional Bicycle Hubs in existence. This week I catch up with Profile Racing‘s Matt Coplon and Corey Alley to find out more about the beginnings and background story one of the most iconic products in BMX. After you check out the interview, don’t forget to check out the PHOTOGALLERY showing you the history of Profile’s hubs!

So to start off you guys brought out the very first Cassette Hub way back in 1997 and it was a pretty revolutionary thing for BMX, how did the idea come about? Who was involved?

Corey Alley: I had been riding MTB and Road for a couple years and got the idea to use a cassette on a BMX hub. There were some companies that did a cassette in the late 70’s/early 80’s but it wasn’t very reliable.

Creating a whole new concept of Hub must have been very difficult from an engineering point of view, I can’t imagine you were able to hit the final design right away, how long did it take until you had a Hub you were happy with?

Corey: The first prototype took about 2-3 weeks and worked well on first go. I thought out the design for a while and was able to produce all the parts in a couple of days. I tried to keep the design simple and maintenance free.

The Hub has been hugely successful ever since its initial introduction, and has somewhat of a cult following amongst riders. I know these days it’s pretty hard to go to your local skatepark and not find at least one person running one, what can attribute this to? Why is the Hub so popular compared to its competitors?

Matt Coplon: That’s a good question? We’re thankful for it (Thanks to everyone out there for the support) but I’m really not sure why?

I guess we could speculate? And this is my personal opinion trying to look at it from the outside. I’m assuming Profile’s longevity in the BMX Industry has something to do with it. I would trust a company a bit more that’s been around for a while/has history.

Specifically on the hubs, considering we control production in-house, it is much easier for us to offer numerous colors/finishes. With that in mind, we can do really small runs of wild variations. We like to mix it up as much as possible to keep things fresh and interesting.

And with our hubs comes a “crash replacement warranty.” That warranty is a “refresher” that covers a discounted rate on hub shell replacement (if broken), new bearings, and labour. It’s a nice little service to have waiting on the backburner if you terrorize your hub. The rest is conjecture…

When you guys first started playing around with the idea of a smaller drivetrain did you ever think it would really catch on? I know I can think of a few famous riders that snubbed the idea of “micro-drive” when it first started to surface.

Matt: I remember a couple conversations I had with riders. Ty Stuyvesant in particular (If anyone knows where he is these days, please let me know! Ha.). He has/had this way of responding with kind of a mumbled, animal type sound build up to “Yes”! He was the first rider to get on it, soon after Mulville and Kevin Porter followed. I truly had no idea it would catch on as well as it did. Funny thing was, the three of them all jumped up to higher gearing eventually. 25/9 is definitely not the most opportune ratio for riding trails.

As far as snubbing the idea, from a technical/physics stand point, they were right. A 25/9 definitely applies more pressure on your drive train. With that in mind, teeth on your sprocket are more susceptible to breaking and chains are more apt to pop. But those factors also depend on how you ride. If you’re an ape, and you really torque down on your drive train (like Mulville), things might not be so good (hence his 30/10). But for most of us, a 25/9 shouldn’t be an issue at all.

How many Cassette Hubs do you guys produce a year? How many do you think have been sold to date?

Matt: I went around the machine shop and tried to gather some info on this. The only thing I could come up with was “a lot.” One of our Euro-techs runs 8 hours a day, 5 days a week producing only hub shells.

Profile is synonymous with producing its products in a wide variety of colours and styles. What have been some of the more memorable finishes that the Hubs have been produced in? What is your personal favourite?

Matt: My personal favourite is black (Ha!). I would say the most impressive colour (giving props to our anodizer) was a one-off Rasta hub we did about 4/5 years ago. It was triple dipped and had three layers of colour: One side was dipped yellow, the hub was then dipped a little farther into the blue tank (making a green centre), then it was flipped and the end was anodized red. Symmetrical, and close to perfect. It was cost prohibitive though, I think our cost (just for anodizing) was $20 a hub.

You are one of the only BMX companies still keeping production within the USA, how important is that to you? Have you ever had any problems with the manufacturing process as you are not based in Taiwan?

Matt: Very important! It keeps all of us employed here at the shop!

With that in mind, production tends to sap at least half of most everyone’s day here. Each of us contributes to an aspect of a part getting out the door: loading in materials, machining, de-burring, preparation for anodizing/painting, and finally the building/packaging of the actual part.

It’s been fifteen year’s since the original Hub was released, how much has the Hub changed in that time? How different is the original when compared to the must current version?

Matt: The biggest change was in 2001 when we stepped down from the High Flange cassette hubs and made the Mini Cassette hub. Converting to the mini shaved a good bit of weight. Soon after, 9t drivers and 14mm axles in titanium were introduced. Now, we’re seeing a lot more 3/8 go out the door (especially with the production of the 3/8 peg bolt).

Other than that there have been small modifications over the years on the driver, springs, paws, and cones. And about 5 years ago we switched the rear spacing from 113mm to 110mm.

Despite a few brands playing around with various different ideas, Hub and drivetrain design has been very standard for years now, can you see any major advancements or changes happening in the near future?

Matt: We’re always toying with ideas here. To make a free-coaster cassette would be the holy grail of bmx, but it just seems so involved: so many potential parts that could very well potentially break.

We’ve been fooling with the idea but nothing has metamorphosed yet.

I remember years ago people tooling with the idea of belt drive. It’s catching on in the MTB scene but wouldn’t that almost defeat the purpose of a bike. The chain is such an imperative part. After all, if you haven’t christened your knee with a bash to the stem (after a chain snapping) then you haven’t lived bmx (Ha!).

Any weird stories or tales involving the Hub you have heard over the years?

Matt: Shane, our warranty guy (sitting next to me), just reminded me of some classic hubs sent in for warranty.

We have had hubs sent in for crash replacement where people have made springs and spacers out of coke cans. Considering our springs are made from brass, it’s amazing that the hubs worked with something as soft as aluminium powering the pawls reflex.

We’ve seen hubs come back that resemble old bomber videos from WW2. You know the ones where a plane comes in with wings blown off, engines missing, etc…but the plane is still somehow flying. It’s incredible really the abuse that hubs can take.

You guys are responsible for some of the most iconic components in BMX, what are you guys working on these days? Do you have anything else in the pipeline?

Matt: About a year and a half ago we introduced the Elite rear hub. With 204 points of engagement, it’s going to be hard for us to modify anything more closer to an instant engagement. As far as hubs go, there is nothing immediate in the works.

On the crank spectrum, we have plenty of new ideas in the works for both Profile (freestyle and race) and Madera.

Actually, as this post, you will probably see the press release for the new Madera HT cranks which we will release first.

Stay tuned!

Now, check out the PHOTOGALLERY showing you some of the different hubs Profile have created over the years.

Be sure to head over to ProfileRacing.com to find out more about their Cassette Hub and other Profile Products.