All Photos: Steve Crandall

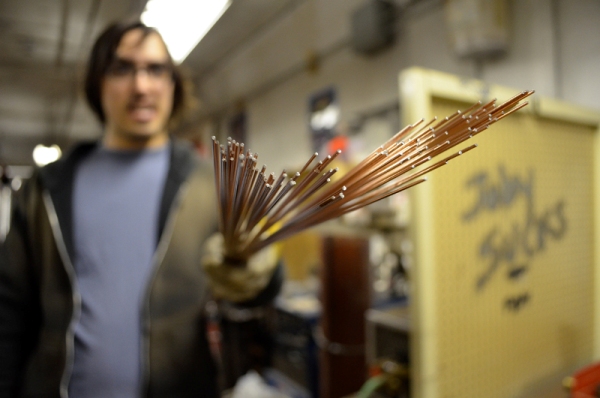

As many of you may know, a few months back Dave Harrison had made the decision to part ways with FBM to pursue some of his other personal goals. With that happening, FBM’s machine shop had to go through some big changes. “Big” Dave was more than just a welder – he helped build the machine shop from the ground up and was the face of the machine shop for many years. This isn’t an easy spot to fill, but FBM knew just who to go with. So we wanted to check in on things and find out more about the man running the welding show these days, Joby Springsteen. Let’s find out a little bit more about Joby, his job and how the transition has been going…

Name: Joby Alan Springsteen

Do you ever feel “persecuted”?

Ha! All the time. Though my name means “Joe Brown”.

Years Riding:

I’ve ridden bikes for as long as I can really remember. So, most of the 23 years I’ve lived.

How long you have worked at FBM:

Almost 3 1/2 years now

Job description at FBM:

Making and welding the bikes. Since june I’ve also been supervising and organizing a couple dudes doing the same thing.

Where did you grow up?

I’ve lived in the Binghamton area for my whole life. That might explain a few things, haha.

What was it like being in with Derek Nelson and the whole HCS scene?

It was a weird year, haha. Derek is a good dude and I learned some things from him and got to do and see some places and things that I wouldn’t have had I not been there.

Ryan Swarts mentioned BCF… what’s that about?

Best Cousins Forever… duh.

Where did you learn to Weld?

For my last two years of high school I escaped to BOCES and took welding class.

What was your motavation to take welding in High School?

Haha as lame as it sounds, it was the Orange County Choppers show that was on. It just made me wonder what welding really was and how it worked so I wanted to know. Also, my older brother went to Boces for electricity so I knew about it as an option.

Since Dave has left how has the machine shop changed?

Well, for a while it was a lot of catching up it felt like. But things are going pretty smooth for the most part. Also Mike has been more a part of the action in the shop keeping communication more open to keep things moving.

What are your thoughts on U.S production verses overseas?

I understand the need for overseas production as far as cost and making price points. I’ve always been a D.I.Y kind of person and U.S made stuff just seems to fit that better along with making sure that things are done right.

Binghamton, NY is a pretty run down city due to outsourcing of jobs overseas, seeing that first hand does that give you any more pride in FBM manufacturing?

When I first heard about FBM being around the area I thought it was really cool. Once I became a part of it I got real pumped because I realized that its a real small operation in Binghamton, New York and we are making bikes that are ridden across the world. It’s awesome. Plus, if this area was in good shape we probably wouldn’t have an affordable space to work in, haha.

Given FBM is sold around the world, what kind of time does it take for you to put together a single frame? I’d imagine you gotta pump a few out everyday, right?

This is the question everyone, I mean EVERYONE asks. If I’m working on a custom bike and have no distractions it could be done in one work day without powdercoat. But everything else is done in batches. Generally we’ll do 20-50 bikes at a time. If we are lucky enough to have all the materials we need we could possibly turn out a batch of 50 bikes in 2-3 weeks start to finish. That means cutting, deburring, cleaning, bending mitering, welding stay assemblies, cap cuts, grinding, more cleaning, tacking, welding, reaming and cleaning. Those are some of the steps each doing anywhere from 40 to 100 parts depending on the batch.

John Lee side note. A custom frame on average takes a week or two due to distractions, production schedule, supplies, etc…. I think Joby means he could weld a frame in one day if he had everything ready to go and wasn’t interrupted He manages two other dudes so he has to monitor what they are doing. So there will always be distractions. – Jeff

Do you have any role in frame design? If so explain the process…

Well, everyone has shared their input when were working on new bikes. From what I know it seems that Mike, John, Steve and Dave were more taking care of that, but we haven’t designed new bikes since Dave left so well see what happens then.

Whats the best part of working at a company like FBM?

There is so much that’s great. I work with and meet great people all the time. It’s a fun job that involves something interesting. Plus, it’s a job that allows me to live.

Besides bikes what else do you like making?

I like making almost anything. Creating is the best part of life because it makes me feel so accomplished. I make little sculptures from metal mostly from time to time, but what I’m most proud of is the musical gear I’ve made; guitar, amp and effects pedals.

Your sculptures look amazing! Has art always been part of your life? Do you also do art on paper or has welding brought out this artistic side?

Well thanks for the compliment. I guess art has always been a part of my life. I’ve drawn a bunch and always liked making things. I’m not trying to sound humble or conceited or anything but I don’t really see much of it as art. I just make things I want to see to the best of my ability in whatever fashion I can. Sometimes I’ll draw things, I’ll weld stuff together, or just spray paint on some cardboard. It’s just things I do when I feel like it. Actually, music is the most dominating for me right now. I more often than not get inspired to make sounds than a drawing or a little robot made of metal. I’m almost always listening to music and it’s the most inspirational thing to me. I’ve been inspired to play guitar from a song but ive also been inspired to try to illustrate it in metal or on paper. I’ve even been inspired to think about things and live my life differently by music. I don’t have any direction or desire to make something of anything I do other than satisfy my own need to do it.

John Lee said music is a big part of your life, in what ways or what music you like?

Like I said before I like building musical gear, but I also play music and its something I want to do forever. It’s the best for of expression for me. As for types of music, it really depends on my mood but some staples are bands like Mogwai, Modest Mouse, Fear Before the March of flames and numerous smaller bands that I’ve had the pleasure of seeing at local shows.

What kind of advice do you have for the people out there looking to get into welding? What about the guys looking to get into welding in BMX specifically?

Learn from someone who actually knows welding and can teach you the basics. Formal classes can be really good with hands on experience. It can be boring but I think it’s the best way. Also, make sure you’re comfortable while welding, it makes all the difference.

As far as getting into welding bikes for a living, I don’t know how many opportunities there are out there. I kind of lucked out with the timing to get the job iI have now. but if you can find a place learn to use a pulsar.

Anything else you want to say?

I don’t drink or smoke. Whether people think that’s lame or cool, BMX bikes are made by down to earth dudes that work hard. I have one of the best jobs I could imagine. I take pride in what I do and i hope people can see the difference and continue to support us.

Do you have any shout outs or thanks?

My mom for supporting everything I do. Big Dave who taught me how to make bikes, John Corts, Mike Corts, Mike Erb, John Lee, Crandall, Kevin the UPS guy, the Reveille staff, Blaze, the shop stereo, Ken Musgrave who dragged himself back to Binghamton a few times this last year to help out welding bikes, and anyone whos been a part of anything awesome! I’d also like to add thanks to you (Jeff Harrington) for doing this interview. Buy American or D.I.Y!